Product Details

Product Details

◆ Paper Material

◆ Size and shape are customized

◆ Glossy and matte finished

◆ MOQ: Usually 500pcs/design

◆ Rotary press printing, offset printing and silk screen printing

◆ Display: by sheet/by roll.

◆ Personalization: perforating, spot UV, foil stamped, embossed, print number, barcode, QR code.

◆Available for: Medical label, food label, wine label, battery labels, carton labels, shampoo labels, bar codes labels, logistic labels, cosmetic labels, beverage labels, wine labels, electronic labels, fruit labels, price labels, hologram labels, stationery labels.

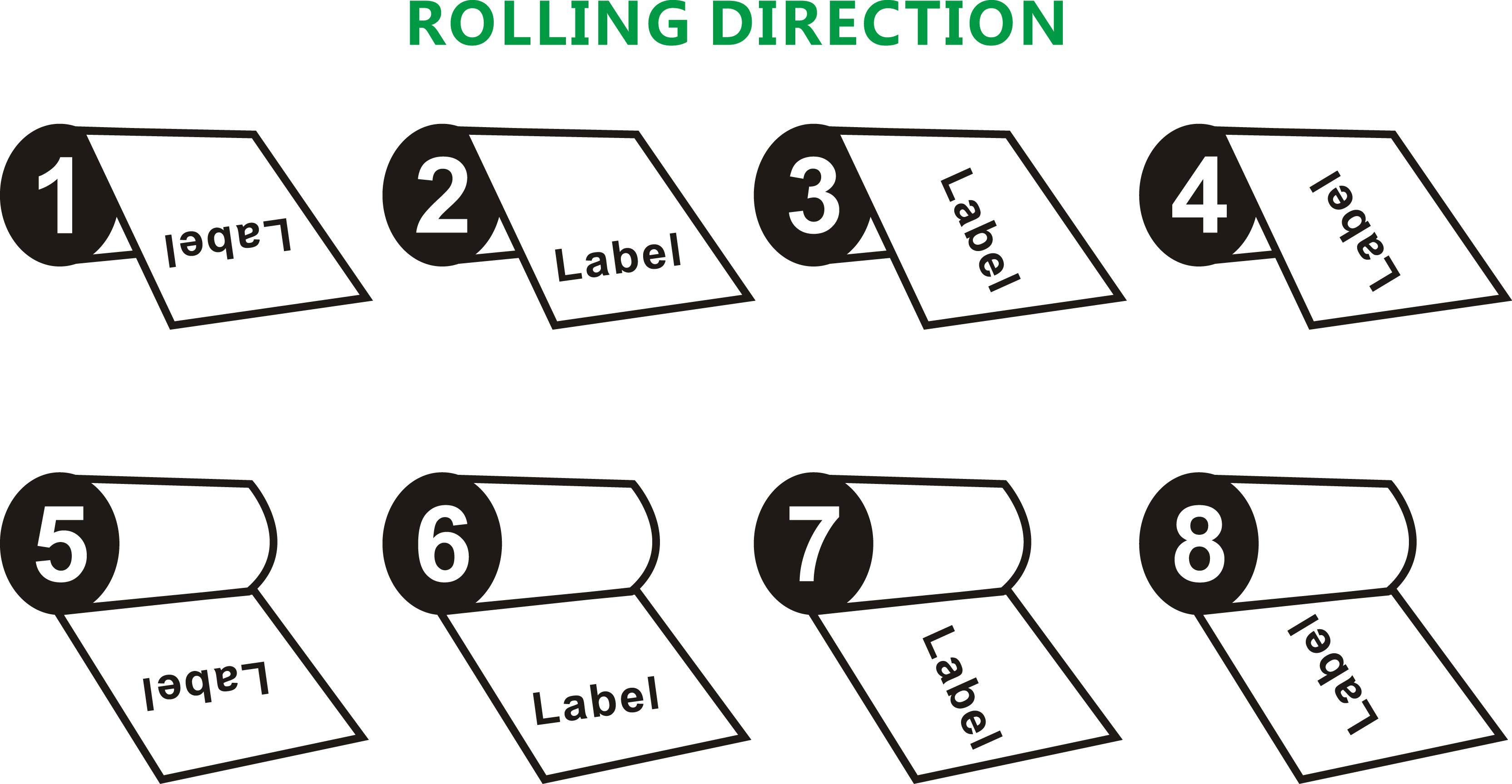

Please choose one of the orientation for your sticker

Application Industry

◆ SPA, Salon, Restaurant, Cosmetology, Gym, Hotel, Club, Advertising, Enterprises, Bank, Insurance, Supermarket, promotion, advertising, bank, traffic, parking, school, access control.

Turnarund, Shipment and Payment

◆ PRODUCTION: It usually take 8working days to print official order, to print sample take 5days.

◆ DELIVERY: Ship to USA by DHL usually take about 3days, to Canda/Australia usually take about 4days. If you are from other countries, please contact us.

◆ We usually ship goods by DHL/FEDEX. By SEA/AIR for big orders.

◆ Payment usually should be done by PAYPAL/TT transfer. For small order, please arrange full payment to start printing. If it is a big order, we accept 50% deposit and rest payment should be done before shipment.

Solid packing

◆ with transparent film wrapped and then in solid carton, waterproof transparent film to protect the carton.

Design format

◆ PDF.AI.CDR.(all texts should be outlined. 3mm bleed size is required.) PSD should be 300dpi or above.

In order to work out specific price for you in time. Please send us inquiry as detail as possible, below is a reference for you.

1. Please send us your details address.

2. Please leave your email and your name.

3. What kinds of sticker are you looking for? Removable or non-removable, waterproof or non-waterproof, out door or in door used?

4. What material the sticker you want it to be?

5. What size of the sticker?

6. What options they are? Are there number, barcode, foil stamped or spot UV or not?

7. Where are the sticker will be stick on? On window, on bottle, on wall, or any other rough surface??

8. How do you want the sticker to display, in roll or by sheet?

9. Do you have design? Please send us, even it is a draft design. Through design, we know which way we will use to print the sticker.

As the prices of different way to print sticker are different.

10. Other special requirement? Please list them.

Printing instruction

Printing instruction

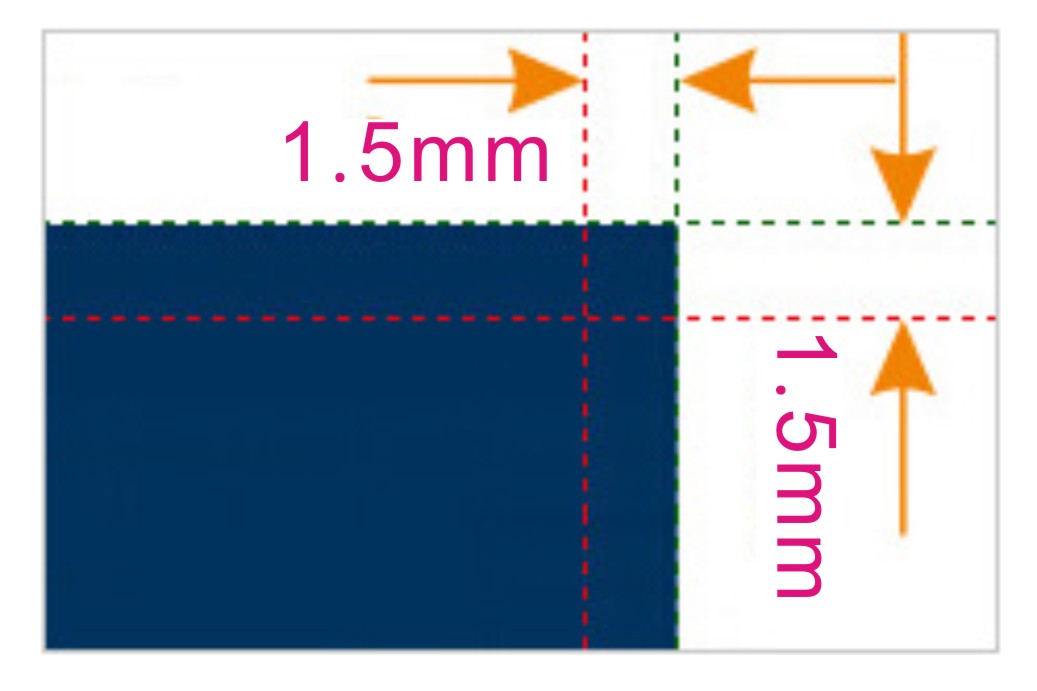

1. Reserved bleeding

There’re product size and printing size. The product size is finished size, 1.5mm bleeding should be added to the product size to increase printing size. The 1.5mm bleeding will be cut after binding. For example, the 85.5*54mm card, if the color pictures or the lines close to the finished size edge, we have to enlarge or extend them to the 1.5mm bleeding to reach the size as 88.5*57mm. This way, there’s no white edge after cutting.

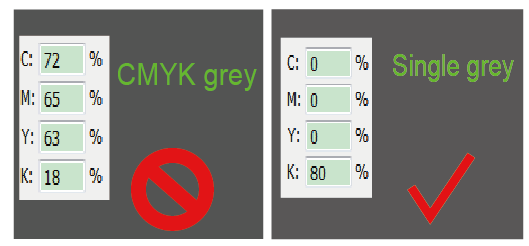

2. About grey color

Please use single grey color / process black, don’t use CMYK grey. Because CMYK grey color is every easy to change, the printing will be blurred and come out with other colors, the finished product is a big difference with original design. If we printed a process black K80, the color won’t change too much, it’s close to the design color after printed.

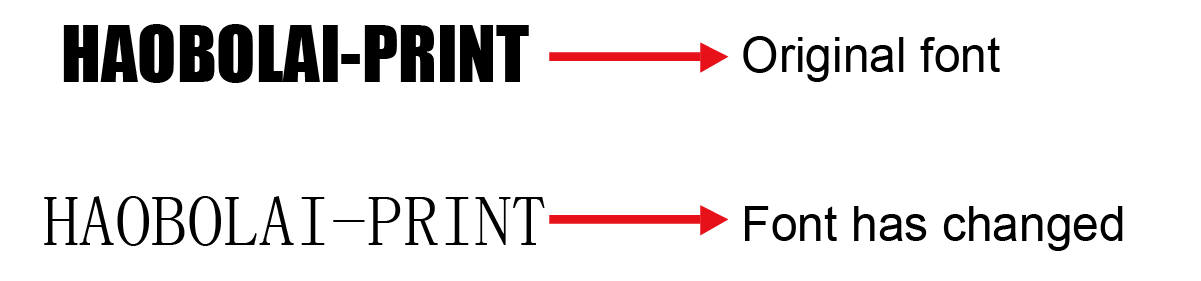

3. About texts

All the texts should be outlined before you save it in PDF/AI/CDR. It means to make all the texts into curves, the font won’t change when it open in any computer, even we don’t have that font you used in thedesign in our computer. If the texts are not outlined, and it happen that we don’t have that font im our computer, the font will change when we open the file in our computer, ssee below you will know the difference. The problem can be solved if you send us that font.

4. About the chromatic aberrations

◆ .Please use professional design software to design.

◆ .Please use CMYK mode to design, don’t use RGB. CYMK mode is

used for printing while RGB mode is for screen. When we converted the RGB to CMYK, some color will change little, some color will have a big changes, the changed colors probably are not the ones you want them to be. So please use CMYK when you design, then you can see a final color of what you want.

◆ .Try to avoid using the easy aberration chromatic. Such as CMYK grey, brown, dark blue, purple.

◆ .If you are stickly on the color, we suggest to use PMS or print sample to check color before bulk order.